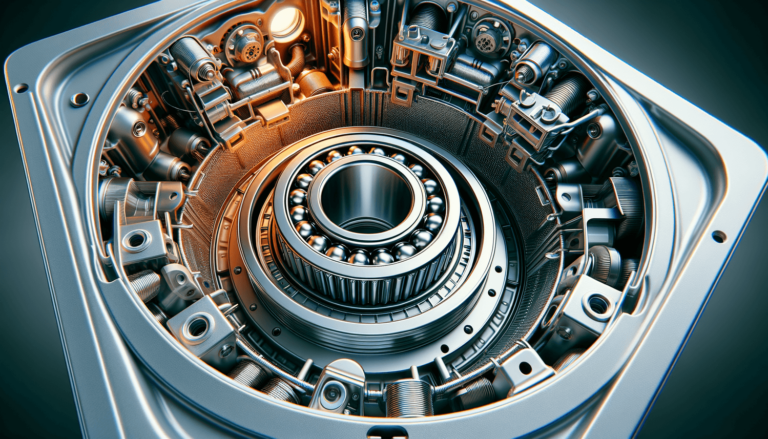

The role of a dryer’s drum bearing is to support the dryer’s drum, reduce friction, and ensure the drum rotates smoothly during operation.

Regular maintenance of the drum bearing can prolong your dryer’s life and optimize its performance. Lubricating the bearing and replacing worn-out parts can prevent further damage.

Selecting appropriate dryer settings is crucial to ensure the longevity of your dryer’s drum bearing. The ‘Settings King’ blog recommends being aware of the dryer settings used, as overdrying or running the dryer at high heat consistently may put additional stress on the bearing.

Some indicators it might be time to replace the drum bearing include excessive noise, difficulty in drum rotation, or noticeable wear and tear. Regular inspections can help detect these issues early on.

Dryer drum bearings play a crucial role in the overall efficiency and performance of your laundry dryer. Understanding their role and the importance of maintaining the bearing is essential for ensuring the longevity of your appliance. In this informative post by Settings King, we delve into the role of a dryer’s drum bearing and share helpful maintenance tips.

The primary function of a dryer’s drum bearing is to support the drum, reduce friction, and ensure the drum rotates smoothly during the drying process. The drum bearing enables efficient and frictionless drum rotation, which can prevent unnecessary strain on the dryer’s motor and other mechanical parts.

The correct use of dryer settings can have a significant impact on the lifespan and performance of your dryer’s drum bearing. As emphasized by Settings King, selecting appropriate settings is key in maintaining optimal bearing performance. Continuously running the dryer at high heat or using improper drying settings for specific fabrics can put additional stress on the drum bearing, resulting in faster wear or even damage.

To keep your dryer functioning efficiently and extend the life of its drum bearing, it’s essential to carry out regular maintenance. Lubricating the bearing and inspecting it for any signs of wear or damage can help prevent future issues. Setting aside time for this maintenance can save you effort and money in the long run by avoiding dryer breakdowns and costly repairs.

Being attentive to your dryer’s performance helps detect potential drum bearing problems early on. Some common signs that your dryer’s drum bearing may need replacement are excessive noise during operation, difficulty in drum rotation, or visibly worn out bearing parts. Regular inspections of your dryer can identify these issues before they escalate and lead to further damage.

Here are some common questions and answers related to dryer drum bearings that might be helpful. These questions focus on the aspects of maintenance, troubleshooting, and efficiency of drum bearings and are intended to provide further insight into the topic.

It is advisable to lubricate the dryer’s drum bearing at least once a year, or as per the manufacturer’s recommendation, to ensure smooth operation and prolong its life.

Use a high-temperature grease or lubricant specifically designed for dryer drum bearings to ensure proper lubrication and compatibility with the appliance’s components.

While some individuals with mechanical skills and experience may be able to replace the drum bearing themselves, it is generally recommended to consult a professional technician to avoid potential damage to the appliance or injury.

Common indicators of a damaged drum bearing include excessive noise, difficulty in drum rotation, or visible wear and tear. Regular inspections can help detect these issues early on and determine if the bearing needs replacement.

The lifespan of a dryer’s drum bearing can vary depending on the usage, maintenance, and quality of the bearing. Proper care and usage can typically extend the bearing’s life to several years before replacement is necessary.